January 10, 2019

Foundry Furnace

[All pics are clickable]

For

years, I've wanted to add some kind of foundry capability to my shop.

Besides being really interesting to me, there have been occasions

where a cast raw piece would have made a fabrication so much easier.

I've made a couple of spin-on oil filter adaptors for old

vehicles, and starting with an aluminum casting would have really

simplified those projects.

So,

a few months ago, I decided now was the time. First, I needed a

furnace. I did quite a bit of research on DIY melting furnaces

and came up with a design that I think should meet my needs at least

for the near term.

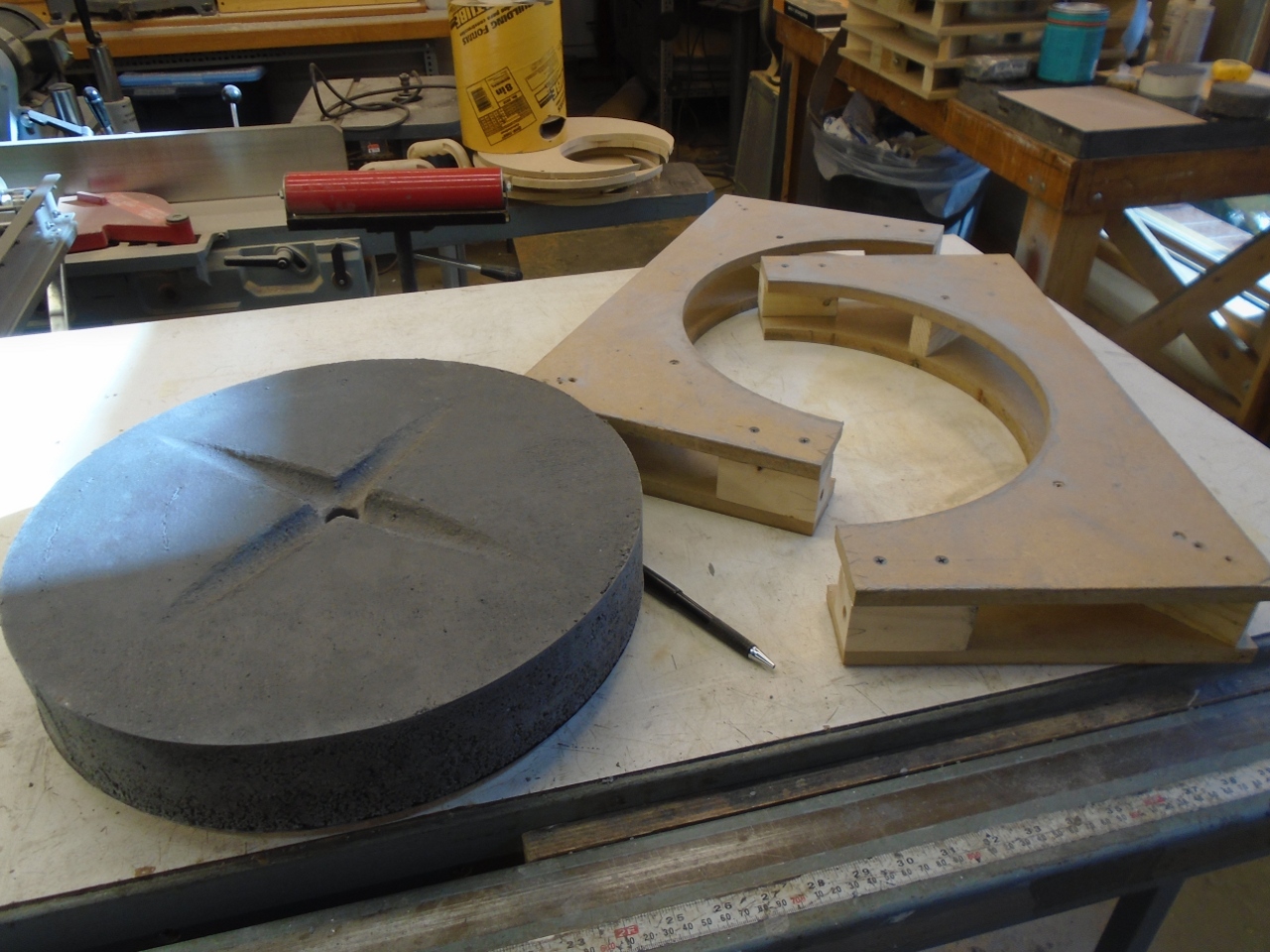

The basic furnace is made out of a castable refractory material allegedly rated to 3000°F.

I

made molds to cast the refractory into. I know that many if not

most furnace builders try to use found objects for the molds--buckets,

tanks, or barrels and such. Making purpose built molds allowed me

to get the exact dimensions I wanted without a search for something

suitable.

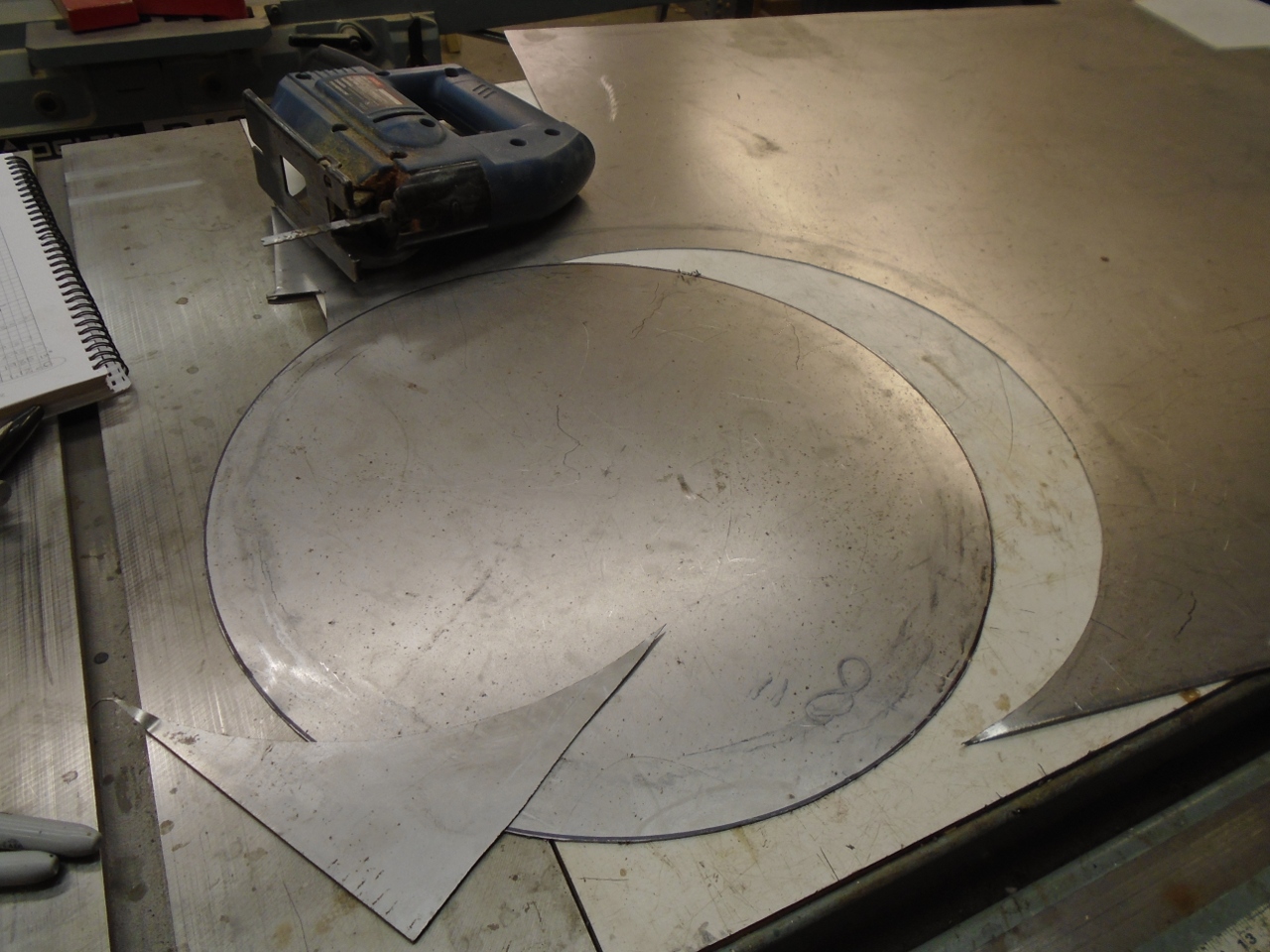

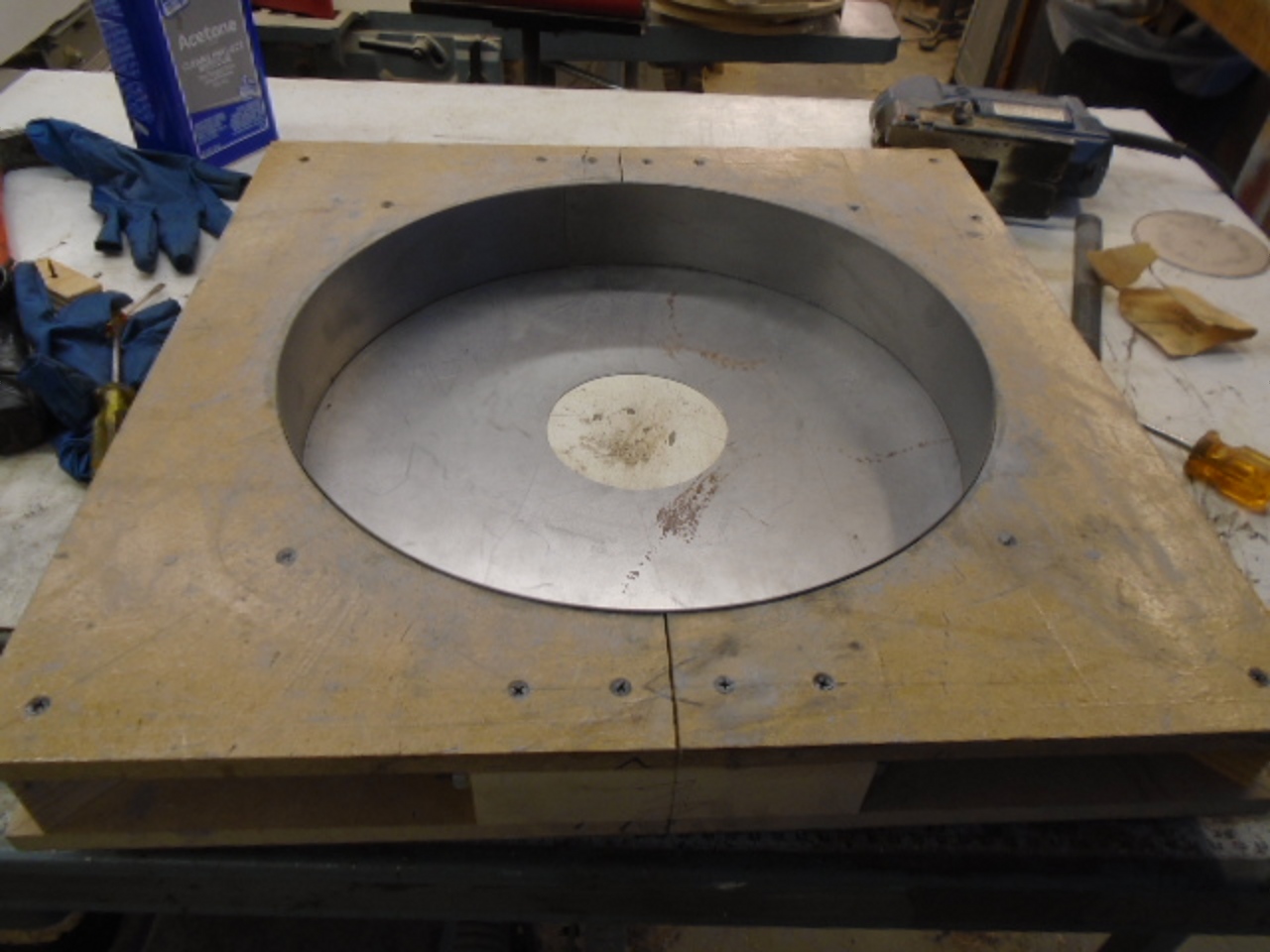

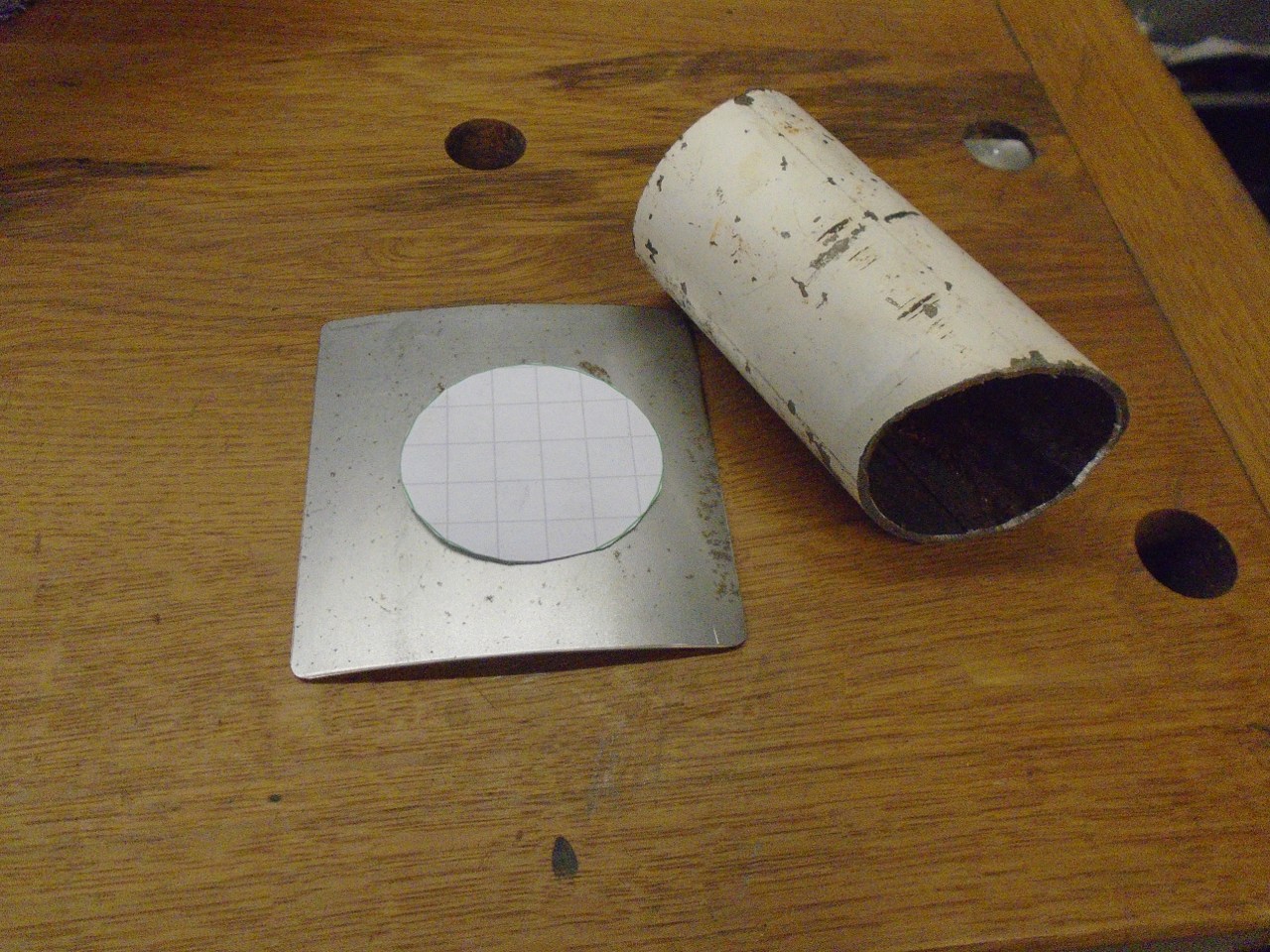

The

base was first. I started with a sheet metal disc that will be

the bottom surface of the furnace. The base mold was set on top

of that, and was lined with some temporary sheet metal.

.

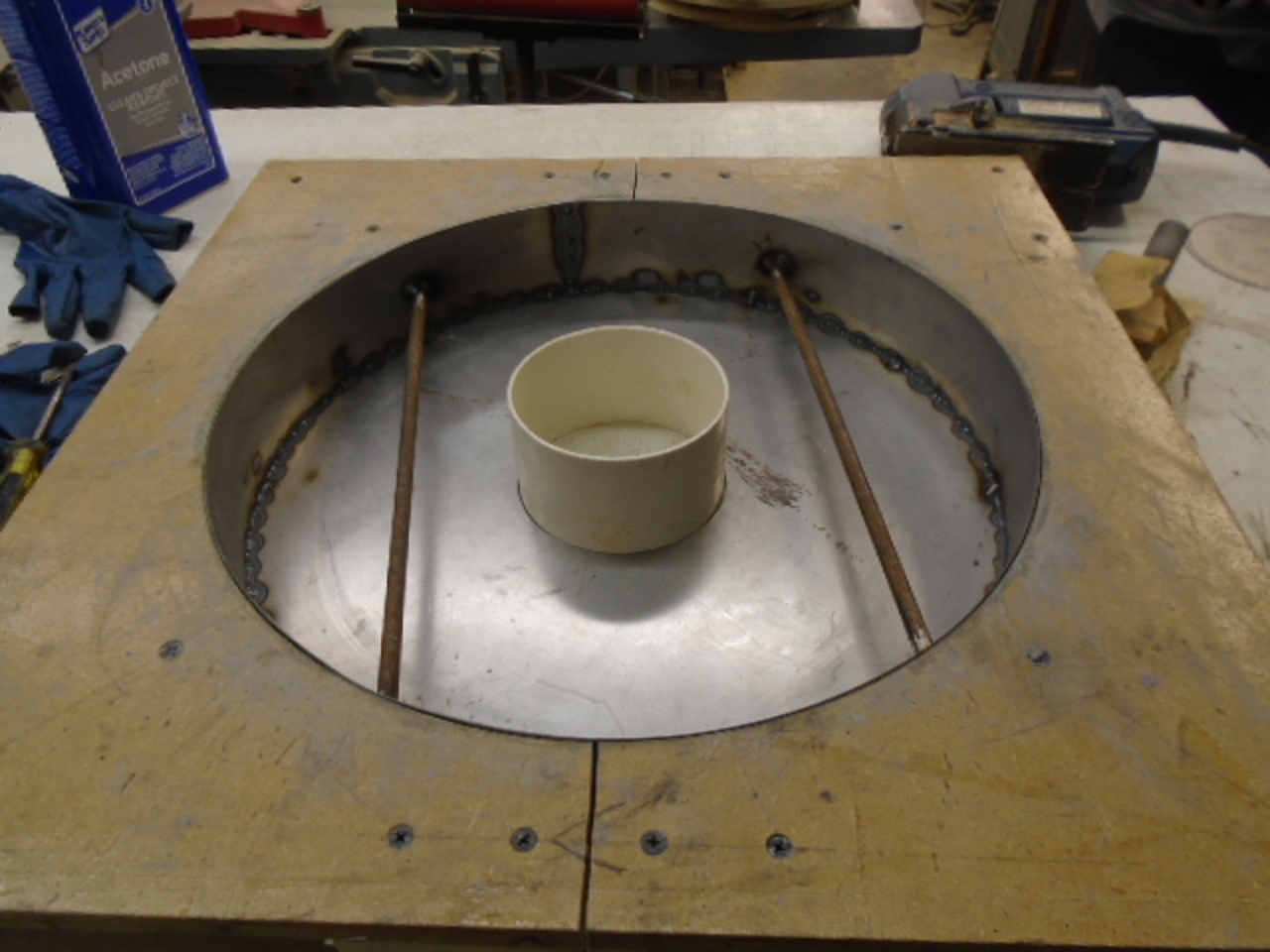

Then

poured the refractory. "Poured" is a bit of a misnomer, since

mixing according to the data sheet results in a very dry mix that

basically has to be pounded into place. Vibration seemed to help

a little, but the data sheet made no mention of it.

The sloped grooves are to direct molten metal to the bottom drain hole in the event of a broken crucible.

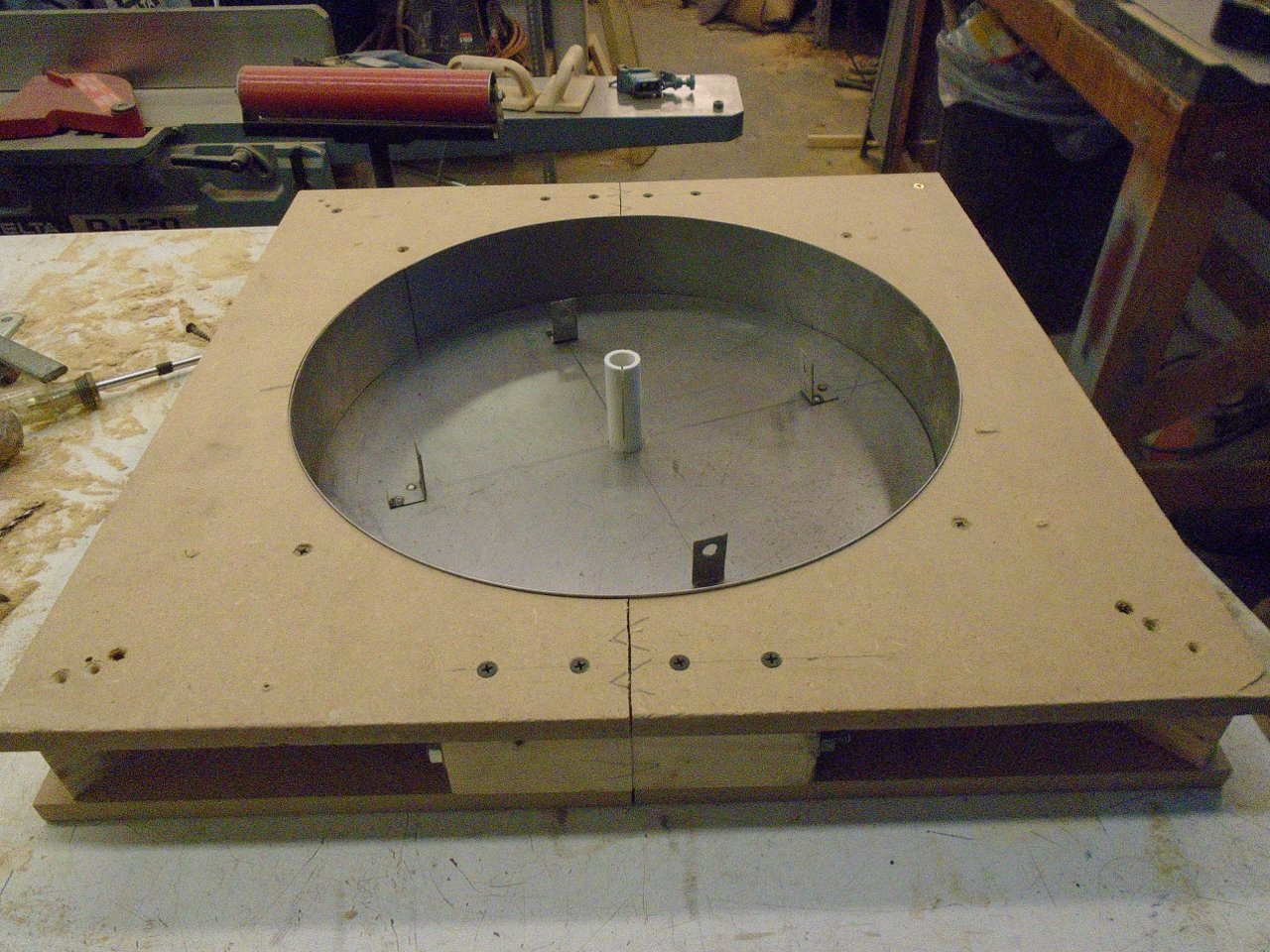

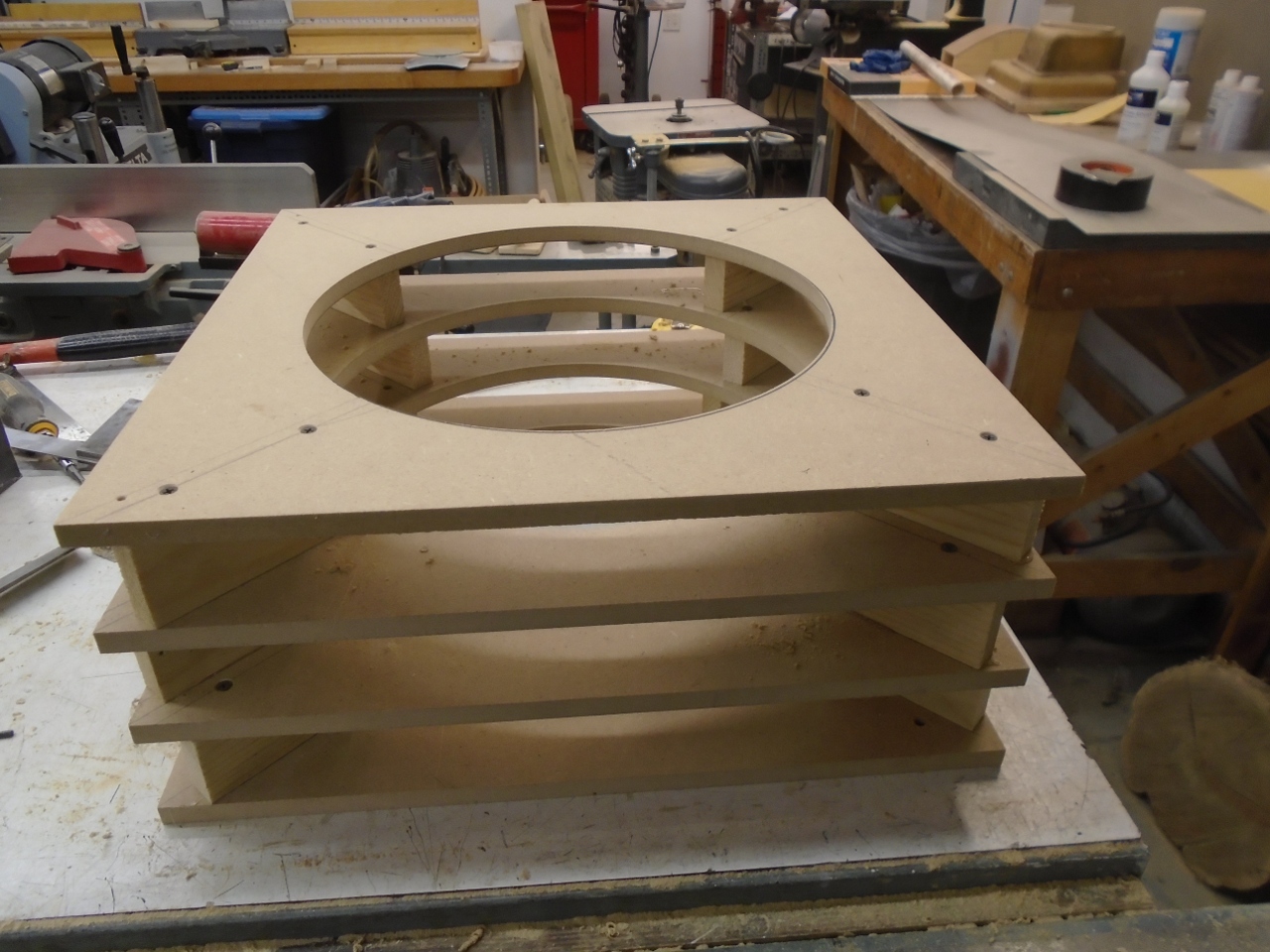

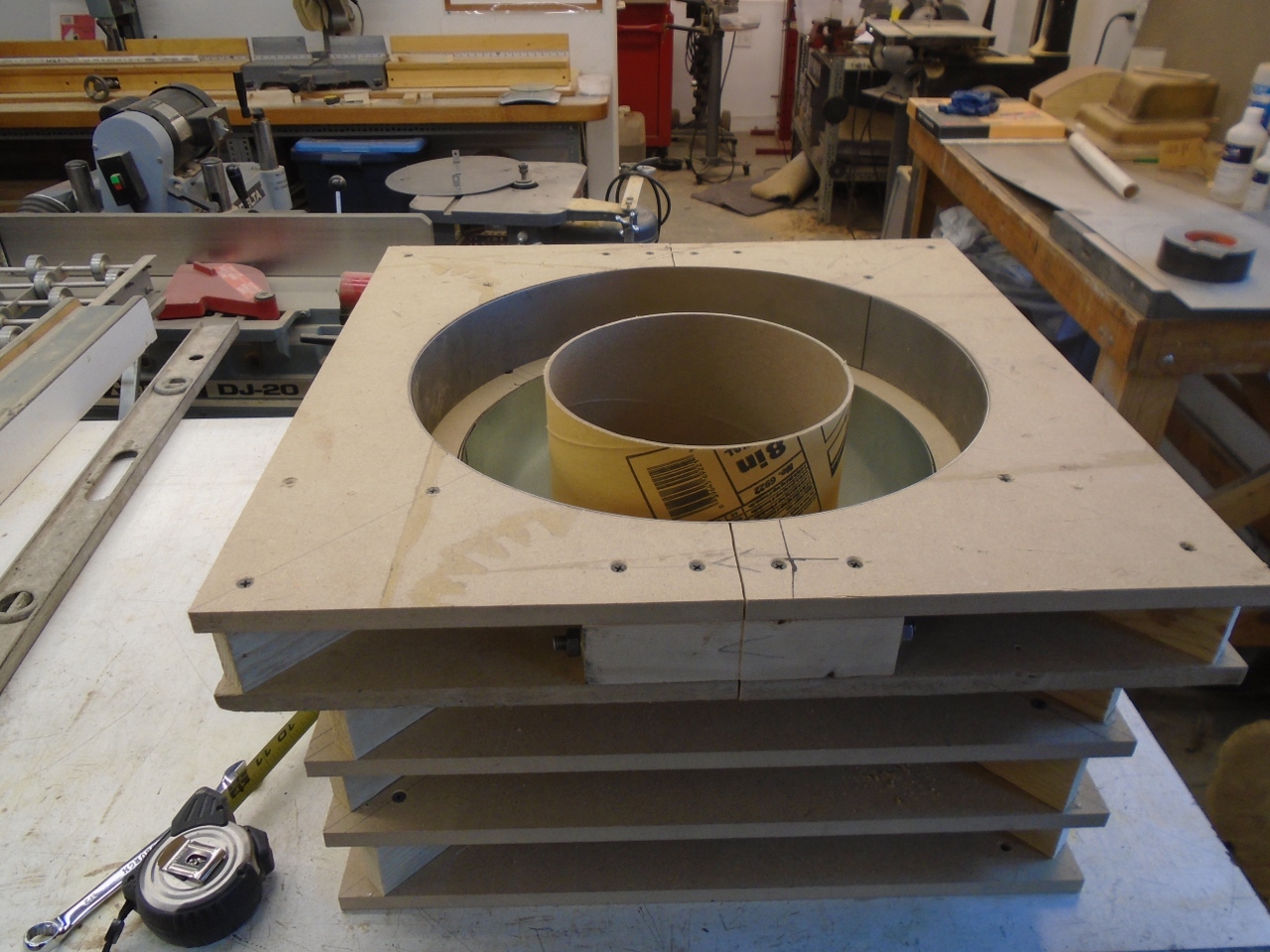

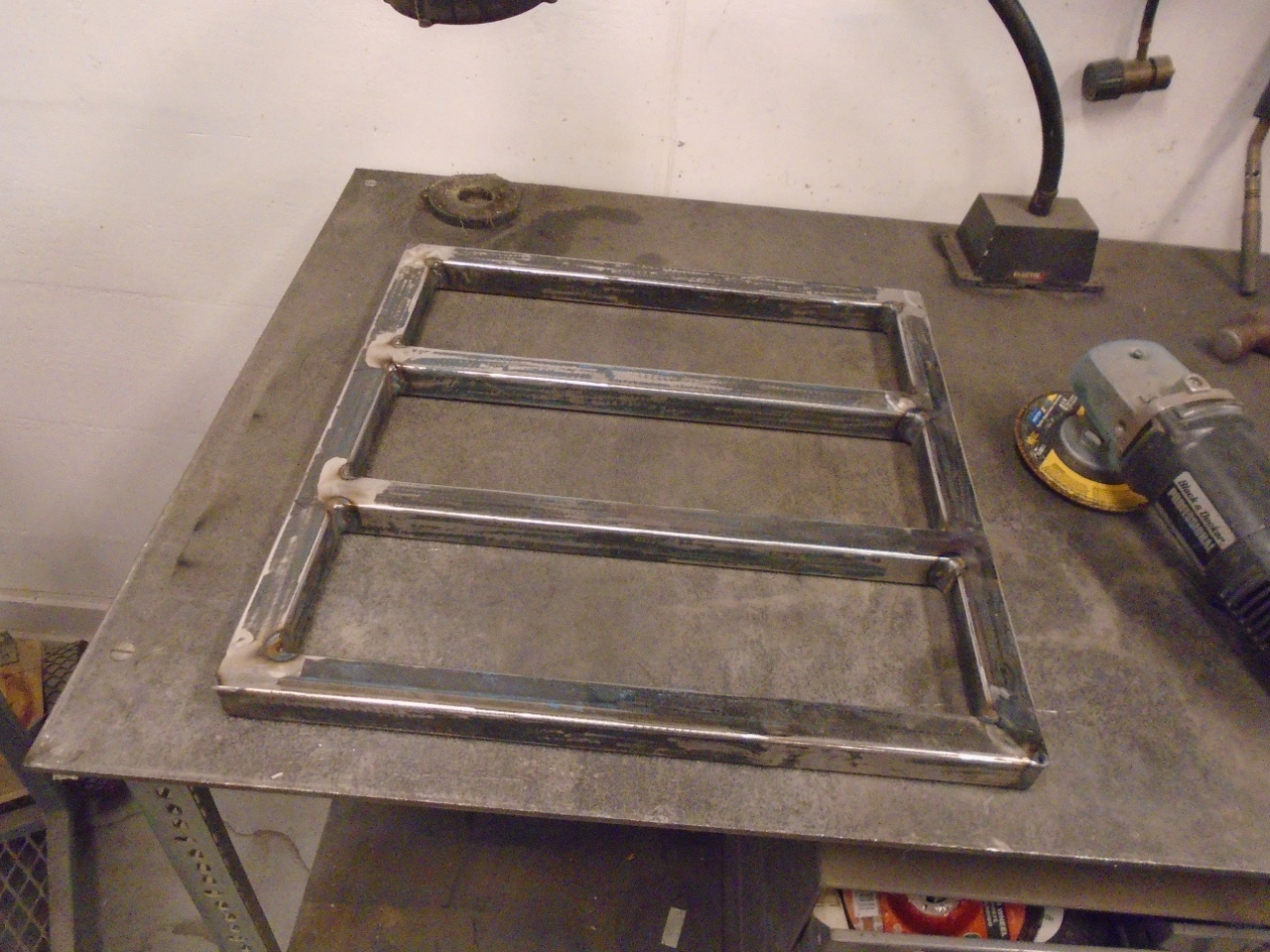

Then

the main body mold. It was in two pieces--one for the belly of

the furnace, and on top ot that, a larger diameter mold to form the top

flange of the furnace. The top mold ia actually the same one used

for the base.

The

lower and upper molds were registered and fastened together, then each

was lined with temporary sheet metal around the perimeter. Then

an 8-inch carboard tube was inserted to form the furnace chamber.

Before

the cardboard tube was put finally in place, I had to cut the hole for

the pipe that would form the burner opening. This is complicated

by the fact that the opening has to be essentially tanagent to the wall

of the chamber. Though there are ways to do this graphically, I

wimped out and used an on-line app that produced a full size pattern

for the hole.

There also had to be a hole for the pipe in the sheet metal lining of the lower mold.

Then

assembled the mold on top of the already cast base to prepare for the

pour. Since the carboard form tube is designed to have concrete

on the inside, not the outside, I treated it with three of four coats

of varnish to hopefully keep it from getting too limp from moisture.

Also, having seen a video or two showing the form tube either

collapsing or trying to float out of the mold, I stacked a bunch of

plywood discs inside with spacers between to fortify the tube.

There is also a threaded rod going up the center of the tube so

that a metal bar can be tightened at the top to hold it down.

The "L" shaped wood pieces were to keep the tube centered in the mold. They moved up with the level of refractory.

Then, in went about 75 pounds of refractory mix.

The next day, removed the molds.

To

make the top or lid, I re-used the same mold used for the base and the

flange of the body. This time, the sheet metal lining the

perimiter of the mold was not temporary. It would become part of

the furnace lid, so it got welded to the disc that would be the top

surface of the lid.

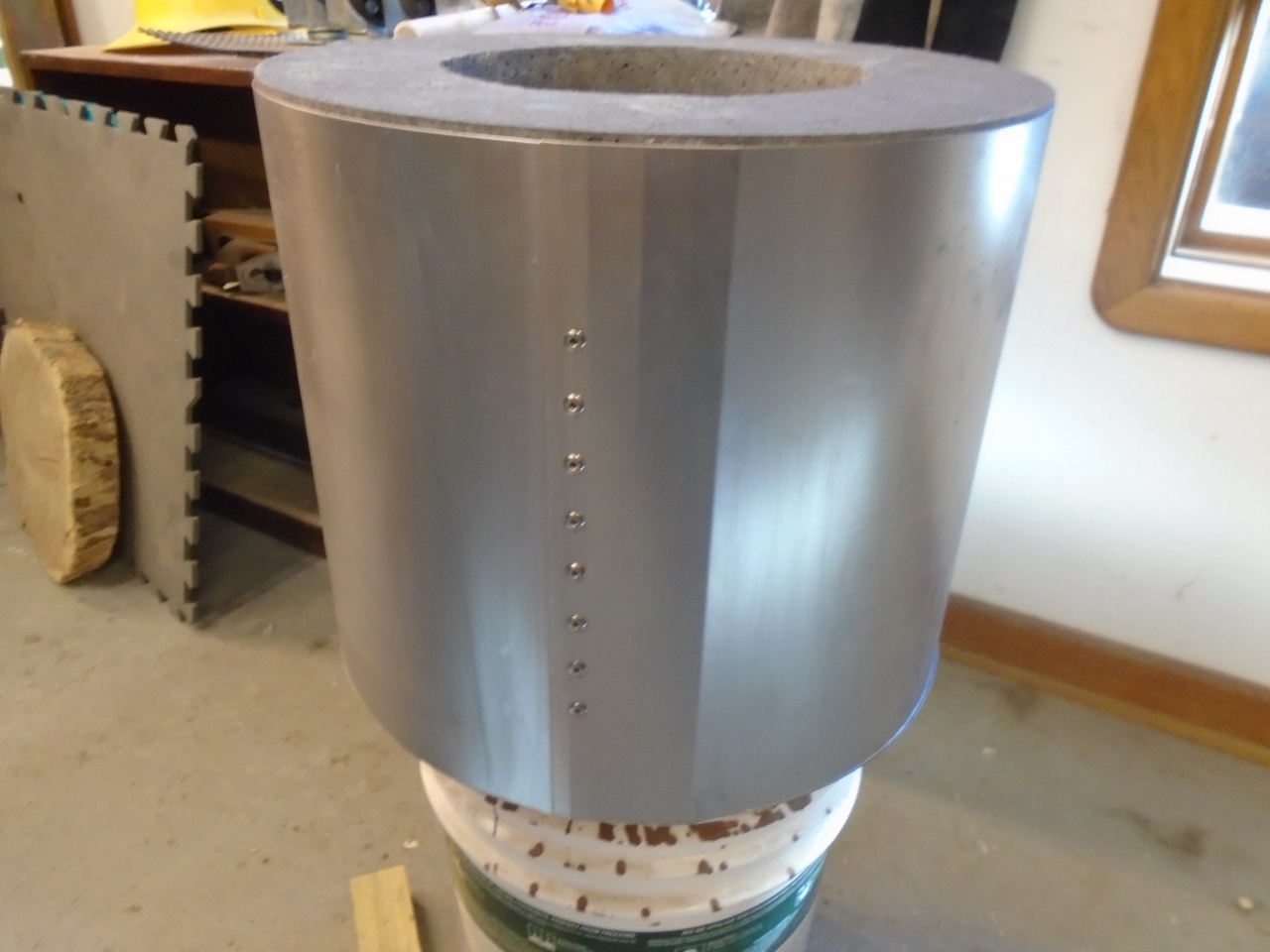

While

the poured top was setting, I turned back to the main furnace

body. A layer of one inch ceramic insulation blanket was applied

to the recess in the outer surface, and a hole cut for the burner to

pass through. The insulation should cut heat loss somewhat, and

maybe keep the outer surface of the furnace a little cooler.

Then, a sheet metal skin was wrapped around the whole thing. It was overlapped and riveted...

...then welded to the bottom disc.

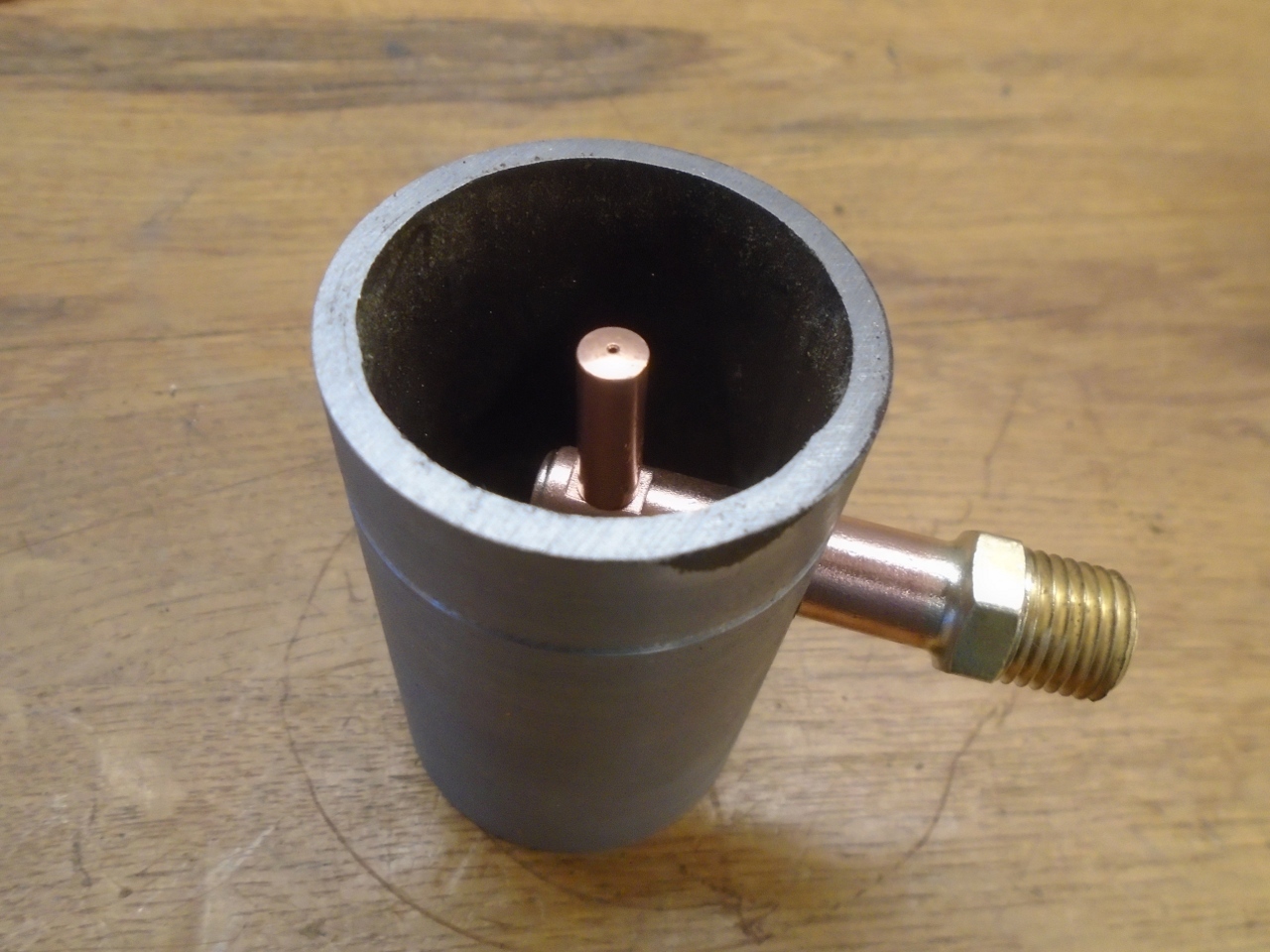

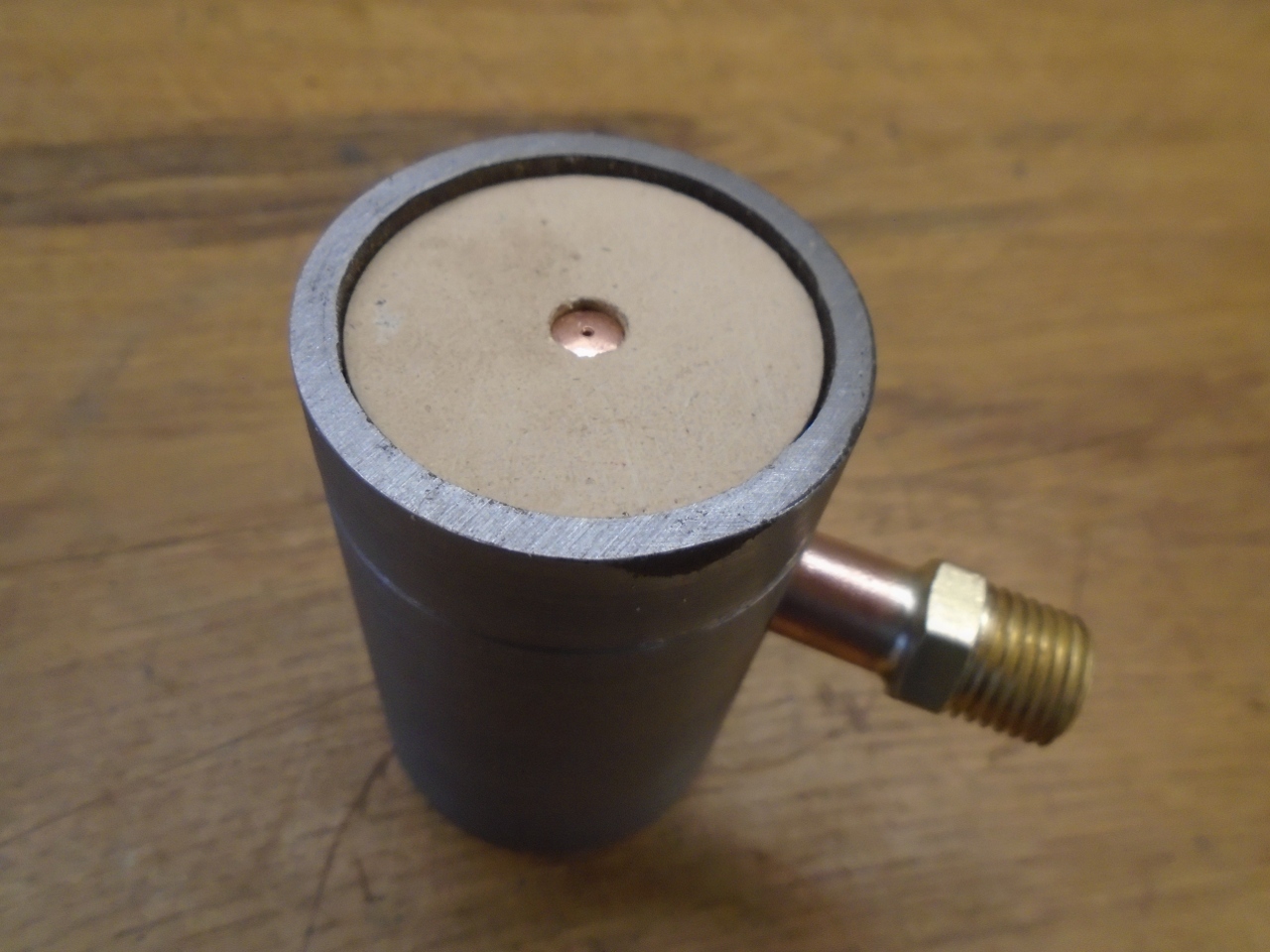

This is a fitting through which the gas burner will be inserted and retained in the furnace.

Then added these rings to sort of bulk up the sheet metal edges of the furnace and lid.

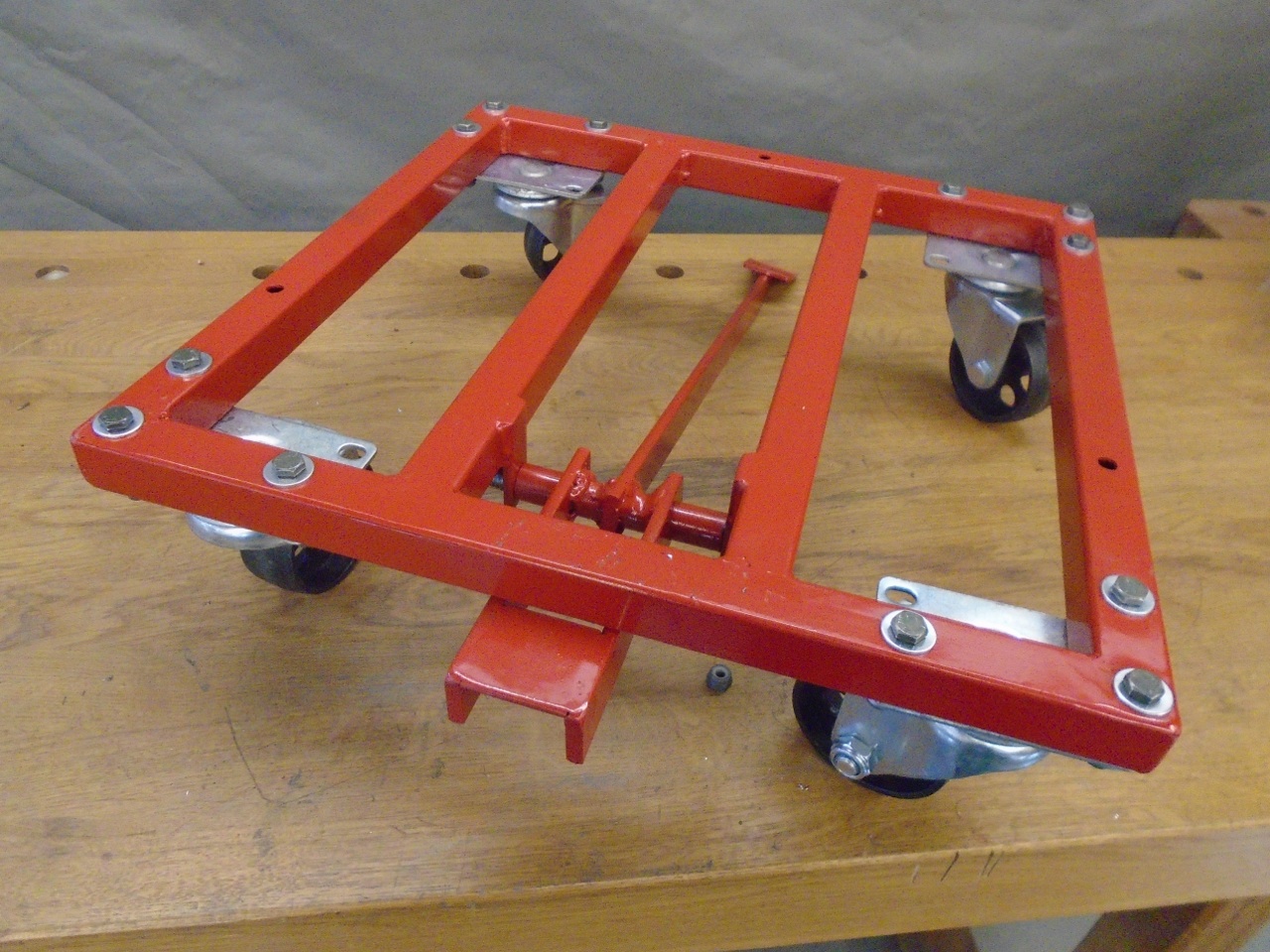

By

this time, the furnace was pretty heavy--around 150 pounds. I

needed some way to make it a little more mobile. I made this

platform and mounted steel wheels on it. Also rigged up the lid

lift mechanism similar to some of those I saw in my research.

Painted everything a fiery red. I know much of this color will be charred with the first burn.

Now,

with the furnace itself pretty well done, I focused on the burner.

I opted to design the burner for propane. Like the

furnace, there are a lot of resources on the Internet describing DIY

burner construction. I absorbed as much information as I could,

and set out to build my burner. It is a variant of a ubiquitous

Reil burner.

The

burner is basically a venturi arrangement with a provision to inject

propane into the air stream. The venturi is implemented with a

reducer pipe fitting. Rather than screw the fittings together, I

opted to turn the threads out of the reducer, and slip in a short

section of 1-1/2 inch pipe as the air tube. It is retained by a

couple of set screws that seat in a groove.

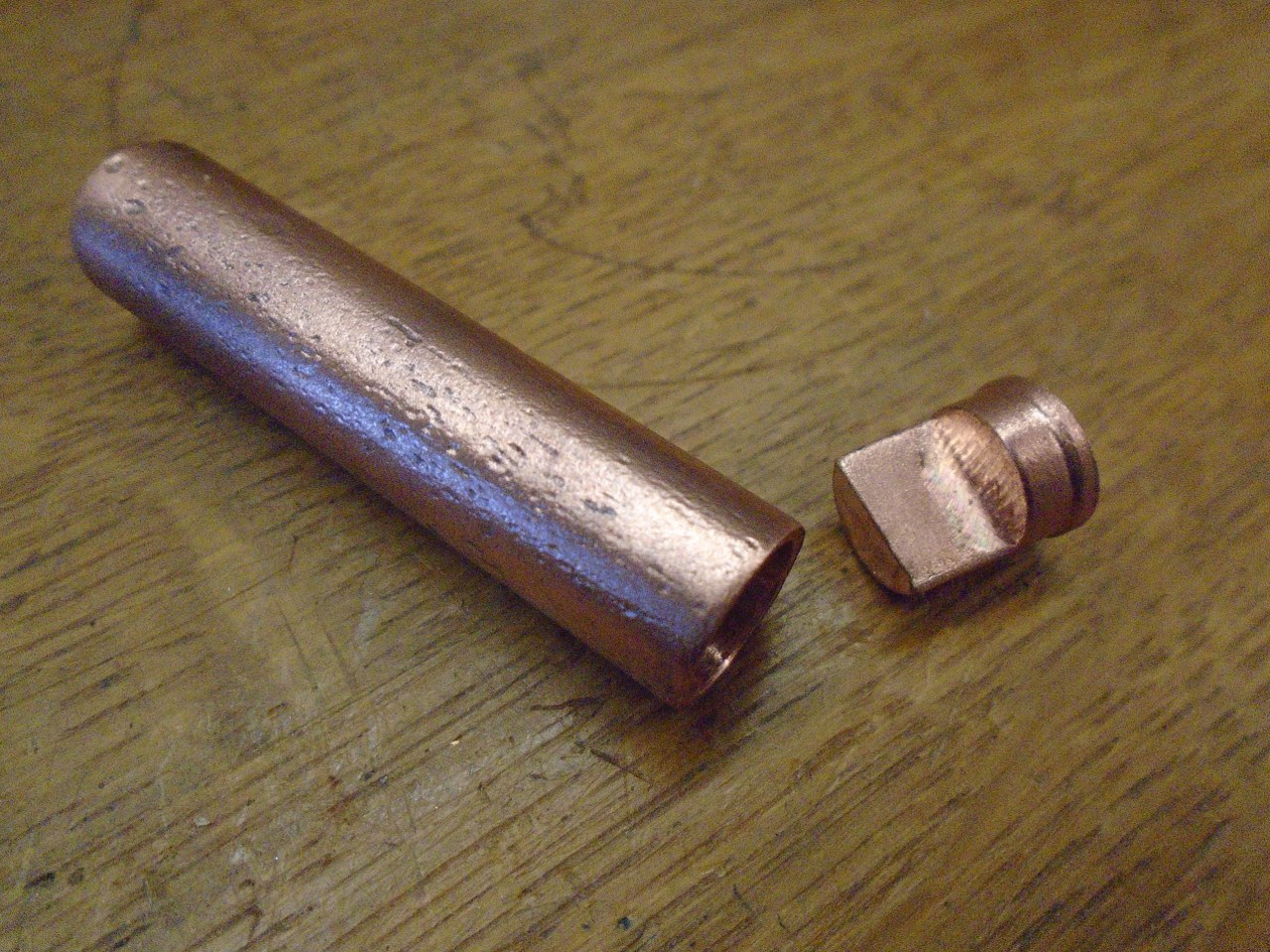

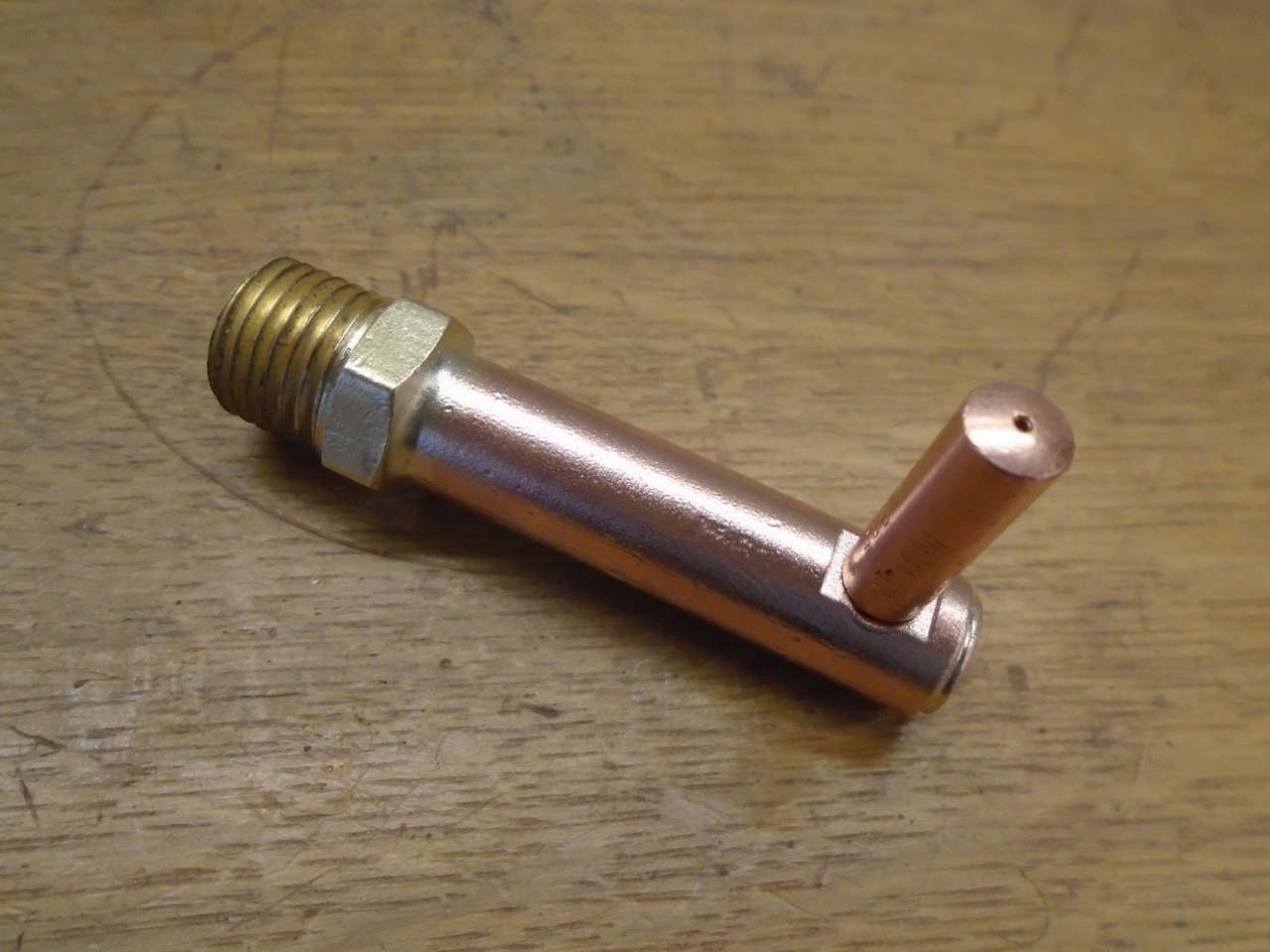

That

short pipe section holds the propane injector. The feed for the

injector is a short piece of brass pipe with a plug silver brazed into

one end. The plug is shaped as to proivide enough meat on one

side so the injector can be screwed into it. The injector itself is a MIG welding tip.

Then a 1/4" NPT fitting was brazed on the other end.

A

hole is drilled in the air tube to accept the injector assembly.

The MDF disc holds the injector centered and aligned for brazing

the gas tube to the air tube.

The MDF was smoking pretty good by the time the brazing was done.

So here is the assembled venturi, air tube, and injector.

The main extension pipe of the burner was then brazed into the venturi.

Most

DIY burner builders like to have a tapered nozzle at the hot end of the

burner. I accomplished this by brazing a short section of 1" pipe

over the 3/4" pipe of the burner, then turned the inside of the smaller

pipe to a taper. It dawned on me a little later that this end of

the burner probably gets hot enough to melt the silver braze material,

so I went back and welded the nozzle piece on.

The

last major thing to do on the burner was some provision for a choke to

regulate air flow. There are a lot of good designs out there, but

this is what I landed on. I started with a 1/4-20 threaded

coupler and added a couple of wings to it. I then welded it into

the air tube so the coupler was centered in the bore.

A circular plate welded to a T handle and a threaded rod forms the adjustable choke.

When

I first inserted the burner into the furnace, I noticed that the nozzle

kind of rattled around in the refractory opening, which I made plenty

large to handle a larger burner. To fix this, I added these three

little bosses to the nozzle. They provide a much better fit to

the refractory opening.

The complete burner assembly:

As a last touch, I mounted a couple of stove handles to the lid.

The furnace is now finished, but I need to wait for better weather to start her up.

Comments to Ed at elhollin1@yahoo.com